Complete Your HVAC Installation Before the Phase-Out of R-410A

As the end of 2024 approaches, the phase-out of R-410A refrigerant is looming, and building owners have a critical decision to make. This transition is driven by new regulations and the introduction of A2L refrigerants, which are mildly flammable and require enhanced safety protocols. Now is the time to act and complete your HVAC installations with available R-410A systems before the new refrigerants bring significant changes to both cost and compliance.

Why Act Now?

Simplified Installation

R-410A systems are widely available and do not require the additional safety features needed for A2L refrigerants, such as mechanical ventilation and refrigerant detection systems. By acting now, you avoid the added complexity and cost of compliance with these new safety requirements.ASHRAE 15 Compliance: The New Reality

Many Mechanical Building Code now incorporates ASHRAE 15 standards to ensure safety when using A2L refrigerants. These updates include:Limits on refrigerant quantity and required installation of refrigerant detection systems.

Immediate actions triggered by refrigerant leaks, such as fan activation and safety shutoffs.

Strict restrictions on ignition sources within ductwork.

Cost Savings

Transitioning to A2L refrigerants like R-454B will require new systems and retrofits, which can drive up costs. Completing your HVAC installation now with existing R-410A units will save you from these increased expenses while ensuring compliance with current safety standards.Avoid Delays and Supply Chain Challenges

As more regulations come into effect, demand for R-410A systems will rise, leading to potential supply chain shortages. Secure your equipment now to avoid installation delays.

Upcoming Changes with A2L Refrigerants

Enhanced Safety Protocols: Requires refrigerant detection, mitigation actions, and mechanical ventilation systems.

Strict Labeling and Storage: Flammable refrigerants require clear labeling, dedicated storage, and increased safety measures.

Act Now: Don’t Miss This Window of Opportunity!

Ensure your building’s HVAC system is installed before R-410A is phased out. Contact us today for a consultation and secure your equipment before it’s too late.

125,000 CFM Air Handler

Discover excellence in industrial HVAC with Advance Industrial Refrigeration's (AIR) latest innovation, the 120,000 CFM Make Up Air Unit (MUA). Crafted to thrive in even the most extreme conditions, this cutting-edge HVAC equipment showcases AIR's unwavering commitment to exceeding customer expectations. Engineered for remarkable performance across a temperature spectrum of 20ºF to 70ºF, our MUA redefines industrial air handling. From its meticulously designed components to seamless operation and innovative assembly process, the 120,000 CFM MUA sets new standards in efficiency and reliability. Step into the future of industrial HVAC – experience the exceptional capabilities of AIR.

At Advance Industrial Refrigeration (AIR), we pride ourselves on manufacturing top-tier HVAC equipment designed to excel even in the harshest environments.

Our latest unit, the 120,000 CFM make up air unit (MUA), is a testament to our dedication to meeting and exceeding our customers' needs. This unit is engineered to deliver exceptional performance within a wide temperature range – from a frosty 20ºF to a balmy 70ºF.

At AIR, we understand that every component matters when it comes to HVAC systems. Here's are some features of what sets our MUA apart.

Working in challenging environments requires equipment that stands up to the test. Our MUA incorporates internal vapor-proof lights to illuminate the unit's interior.

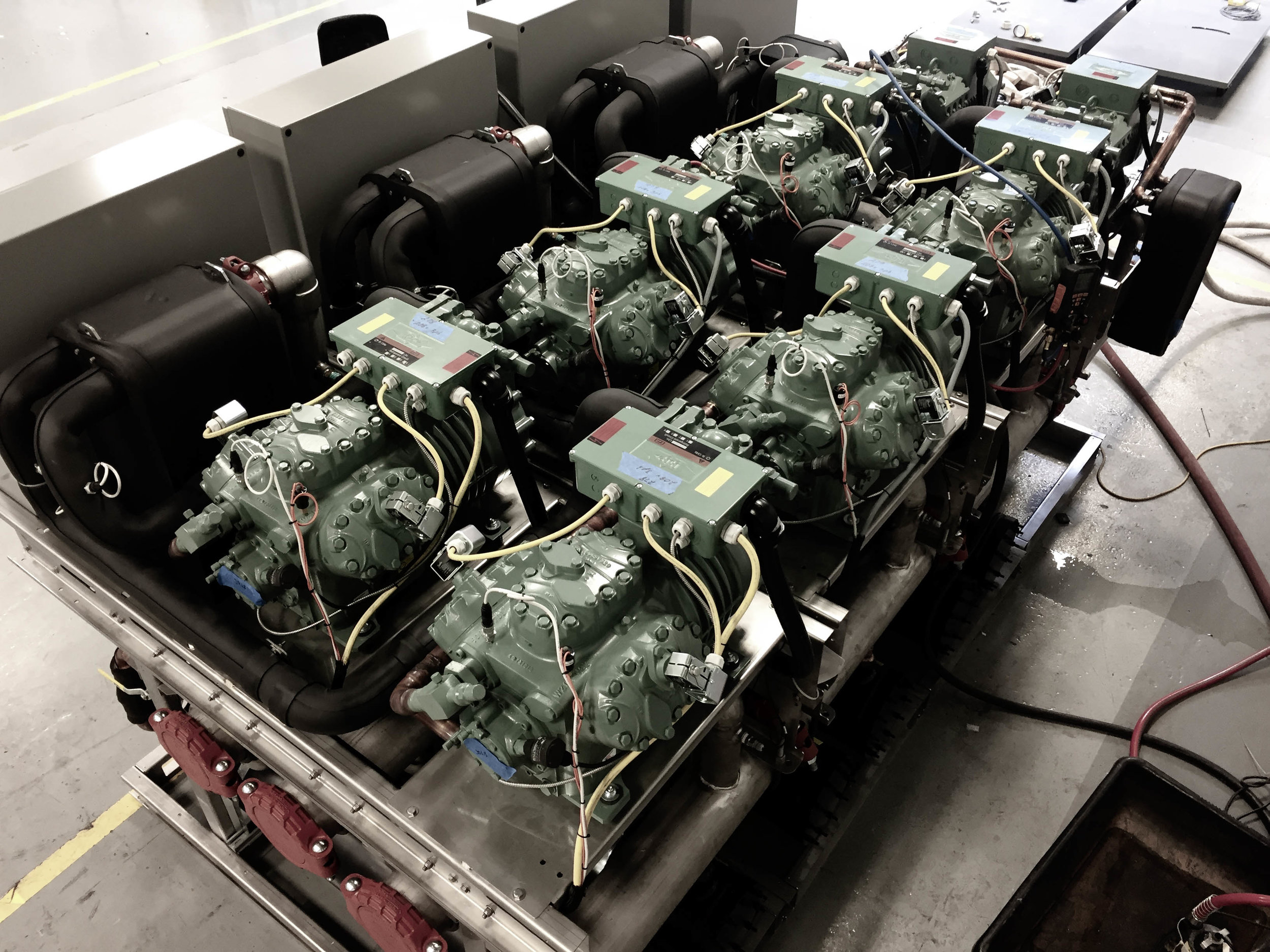

The heart of our MUA is the backward-inclined balanced G2.5 DWDI fan. This fan, coupled with a spring isolation base, extended bearing lube lines, and a robust belt guard, guarantees exceptional performance while minimizing vibrations and enhancing longevity.

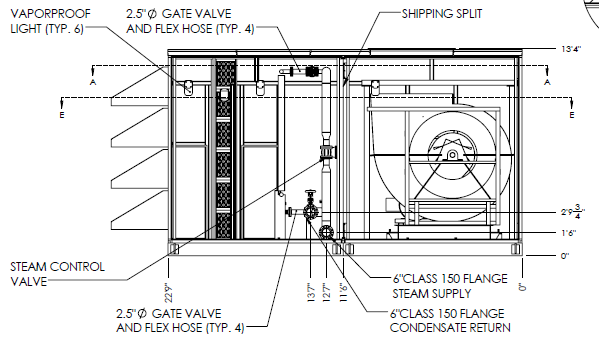

Seamless operation is at the core of our design philosophy. Our MUA with steam heating coils comes pre-installed with a Fisher Steam control valve and gate valves, allowing for precise steam control and ensuring optimal efficiency. The unit is equipped with 150 psig ANSI flanged connections for steam and condensate lines, perfectly matching existing unit connections and simplifying the installation process.

We have a great understanding of the logistical challenges of large units, we've designed our MUA to be shipped in two sections, which are then assembled on-site under our expert supervision. This innovative approach streamlines transportation and installation, saving time and resources.

Quality assurance is our top priority. To ensure that our unit performs flawlessly, every unit undergoes a meticulous factory tests. Furthermore, we take pride in offering on-site supervision and support during unit assembly, ensuring a smooth and trouble-free installation process.

The 120,000 CFM Make Up Air Unit from Advance Industrial Refrigeration is a true testament to our dedication to crafting reliable, efficient, and high-performing HVAC equipment. With features ranging from advanced fan technology to thoughtful on-site support, this unit is poised to revolutionize industrial air handling applications. Experience the future of industrial HVAC – experience AIR.

Beyond social distancing...do you want to protect your team and customers from the Coronavirus?

AdsorbAIR pressurization units are designed to maintain a G1 reactivity level within corrosive rooms, as defined by ANSI/ISA Standard S71.04-2013. In addition to AdsorbAIR, RecircAIR recirculation units are recommended for spaces that have high traffic levels, very dusty environments, or are critical to overall plant operation. The addition of recirculation allows reduced recovery times for increased contaminant levels due to entry into the pressurized space. The activated carbon media oxidizes airborne contaminants, breaking them down to harmless components.

In these uncertain times, protecting team members and customers from exposure to the COVID-19 virus is a priority for us all. The CDC recommends the following “guidelines” for airborne infection isolation rooms:

Minimum of 12 air changes per hour

Filter recirculated air with HEPA (High-Efficiency Particulate Air) filtration – 99.97% efficiency @ 0.3 micron particle size

While conference rooms, control rooms, and lobbies are not medical isolation rooms, asymptomatic team members can release Coronavirus aerosol droplets that are extremely small and will remain airborne for a long duration. Room recirculation through HEPA filtration will remove these droplets, reducing airborne exposure duration and contamination on surfaces within the room.

Repurposing of our RecircAIR unit provides a cost effective option for Coronavirus protection. This requires temporarily mounting HEPA filter(s) within the carbon media section. Post-filters after the HEPA filter are not required. This provides protection for the following room volumes:

RecircAIR Model RCR-100

(1) Recirculation Fan rated for 1,000 cfm

12 air changes per hour for a total room volume of 5,000 cubic feet

RecircAIR Model RCR-200

(2) Recirculation Fans rated for 1,000 cfm each (2,000 cfm total)

12 air changes per hour for a total room volume of 10,000 cubic feet

Due to the MERV 8 and MERV 15 pre-filters, the HEPA filter will typically last for years and should not require replacement during this national health emergency. Once the threat of the Coronavirus has passed, the RecircAIR unit can then easily be repurposed to protect electrical spaces from corrosion related electronic failures by:

Relocating the RecircAIR unit to the protected electrical room

Removing the HEPA filter

Installing the carbon media modules and post-filters provided at the time of purchase

AIR is offering this as a cost effective solution to provide our customers with a means of protecting their team members with a product that also addresses their corrosion control needs in the future. A brochure of the RecircAIR unit is attached for your information. Contact us if you have any questions or would like more information.

Categories

-

September 2024

- Sep 5, 2024 Complete Your HVAC Installation Before the Phase-Out of R-410A Sep 5, 2024

-

July 2024

- Jul 8, 2024 50 Ton Unit Installation Jul 8, 2024

-

August 2023

- Aug 21, 2023 125,000 CFM Air Handler Aug 21, 2023

-

April 2020

- Apr 3, 2020 Beyond social distancing...do you want to protect your team and customers from the Coronavirus? Apr 3, 2020

-

December 2018

- Dec 12, 2018 MODULAIR – AIR-COOLED MODULES NOW AVAILABLE! Dec 12, 2018

-

November 2017

- Nov 16, 2017 INTRODUCING MODULAIR- A COMPACT WATER CHILLER WITHOUT COMPROMISE! Nov 16, 2017

- Nov 16, 2017 HEAT EXCHANGERS COMMONLY USED FOR EVAPORATORS AND CONDENSERS Nov 16, 2017